PRECISION, DURABILITY

CONSISTENCY

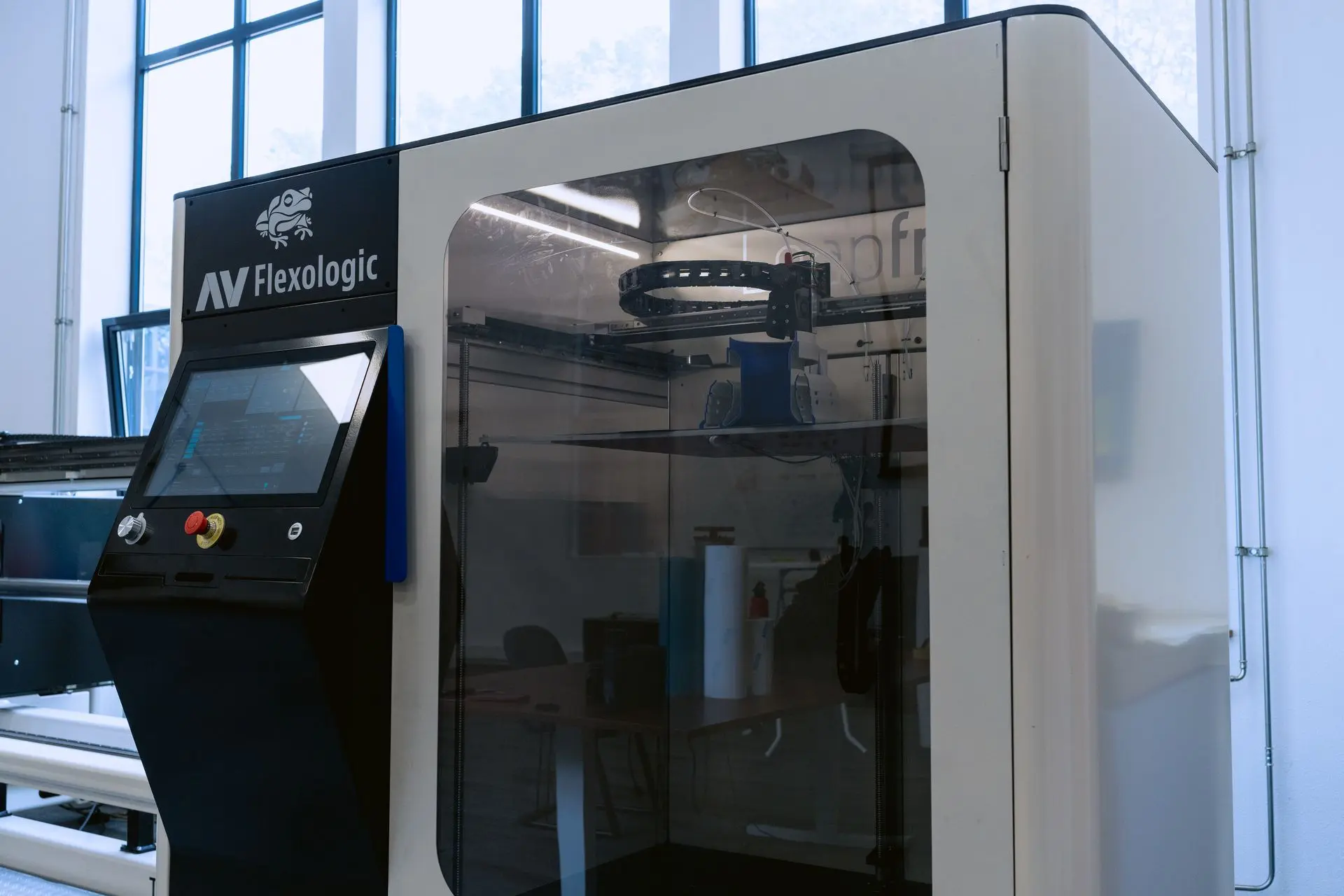

The ultimate solution for fully automated industrial 3D printing. Leapfrog ONE is designed to meet the most demanding industrial requirements with unmatched precision and efficiency.

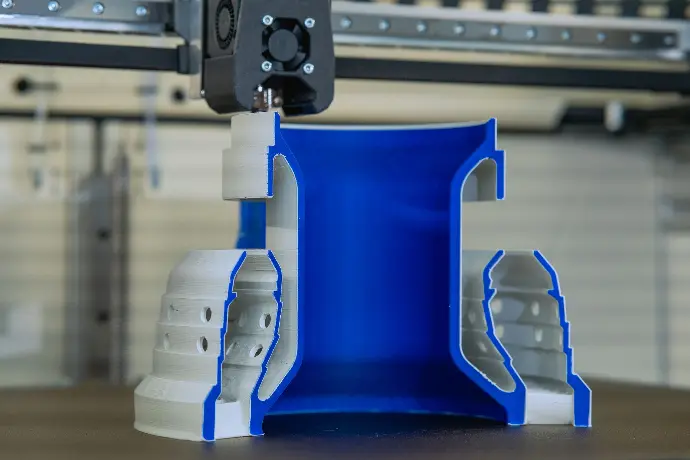

Revolutionary Features for Superior Performance Independent Dual Extruder (IDEX)

Achieve multi-material and multi-color prints with ease with Leapfrog ONE. The IDEX system allows for the use of soluble supports, creating complex geometries and functional parts as well as giving you the possibility of multi-material or multi-color 3D printing. This results in an enhanced design flexibility, improved print quality, and significant cost savings by reducing material waste.

Triple Z-Axis Design

A robust, triple Z-axis design takes the tedious bed leveling calibration completely off your hands. It automatically measures the bed location at 3 different points after which it mechanically alligns the print surface to the printheads.

Building upon the self-calibration, each tool includes a smart and automated Z alignment system, enabling you to use different tool types and lengths for full production flexibility.

High-Speed Printing

Equipped with the HAQ-XY motion architecture, Leapfrog ONE is capable of printing with speeds up to 200mm/s at high accelerations of up to 10,000mm/s².

Travel moves run even faster at 500mm/s at 15.000mm/s² accelerations. These combinations drastically reduce your lead times and increase production efficiency, allowing for faster iteration and development cycles.

Large Build Volume

A spacious build area of 600x500x800mm gives you the canvas for limitless possibilities such as rapid prototyping, large-scale industrial projects, production of jigs/fixtures, single-production art pieces or small-batch production runs with minimal leadtimes.

On-Board Slicing

Integrated slicing software allows for on-device slicing, eliminating the need for external software or extensive production knowledge and simplifying the workflow.

With Leapfrog ONE, all users with various experience levels can make use of the capabilities of 3D printing.

Advanced Capabilities and ROI

Leapfrog ONE supports many 3D printing materials such as PHA, PLA, PETG, ABS, ASA, PC, TPU and PA to be ready for all your applicational needs. The ONE platform is also ready for future innovations around filament climate control and heated printing chambers enabling you to print even more advanced materials like PEEK, PEKK, and ULTEM for the extremely demanding situations.

Connectivity and Automation

Leapfrog ONE offers a printing queue management and is ready to support future integration with ERM systems and CAD-software. This in term results in an extremely streamlined workflow, efficient job prioritization and a seamless integration into your production ecosystem.

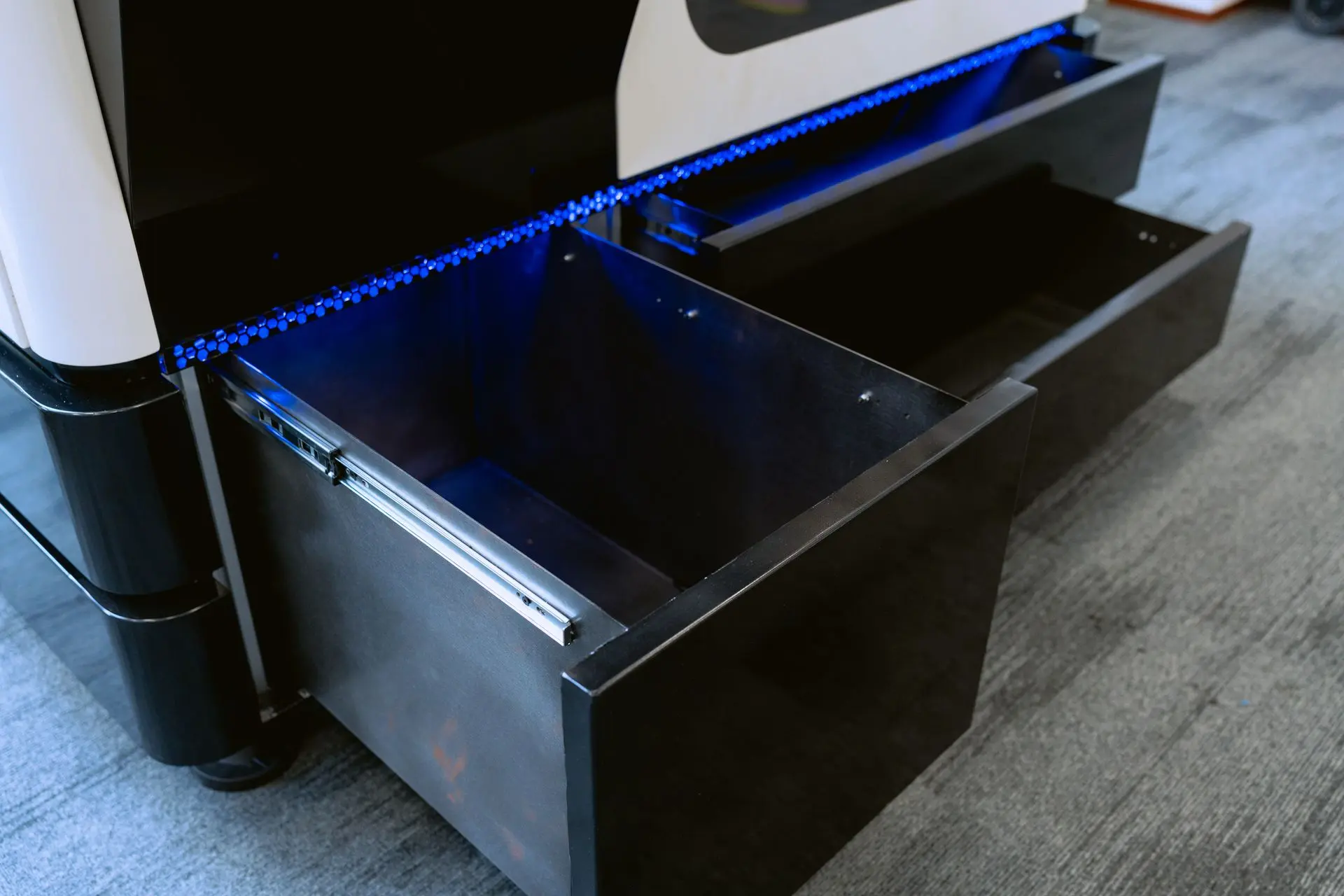

Storage Solutions

Integrated cabin storage is included to neatly store your filaments and spare parts, supporting rolls up to 3kg. and various spaces for tools, spare parts and prints. Resulting in an organized workspace to aid uninterrupted printing.

Modular Tool Design

The quick-swappable nozzles and modular tool design allows for easy maintenance, quick replacements and potential future upgrades, such as laser engraving and milling.

About Leapfrog ONE

Automation

- Bed calibration

- Fully self leveling bed (mechanical)

- Printhead calibration

- Fully automatic XY

- Fully automatic Z (mechanical)

- Print surface compensation

- Fully automatic

- Fully automatic slicing

- Fully automatic

Extrusion System

- Configuration: IDEX (independent dual extruder)

- Extruders: Geared and hardened stainless steel drives, powered by Bondtech

- Nozzles: Quick swappable exosystem, powerd by E3D

- Stock nozzle size: 0.5mm

- Max nozzle size: 1.4mm

- Maximum extruder flow: 52mm3/s

Production Speed

- Maximum printing speeds; up to 200mm/s

- Maximum printing accelerations; up to 10.000mm/s²

- Maximum movement speeds; up to 500mm/s

- Maximum movement accelerations; up to 15.000mm/s²

Machine Details

- 1.75m x 1.10m x 1.80m

- ( Width x Depth x Height )

- 3 Built-in Drawers

- LED chamber lighting

Motion

- Build volume: 240 Liters (600x500x800mm)

- Motion architecture: HAQ-XY

- Z-Movement System

- Triple Z-Axis Design

- Live speed tuning: Built in accelero meters ²

Materials

- Filament; 1.75mm

- Spool size; up to 3KG

- Material support: PLA, ASA, ABS, PETG, PC, Nylon

Safety

- LED status indicator

- Emergency stop button

- HEPA and Carbon filters